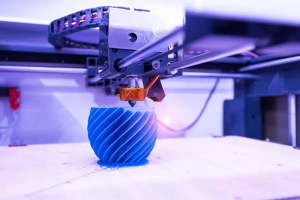

Unlike your granddad’s daisy wheel printer or mom’s dot matrix, 3D Printers print in three dimensions. They’re becoming commonplace in garage workbenches, design studios and rec rooms.

Models are sliced using software that tells the printer what to do layer by layer. This allows manufacturers to create prototypes faster and reduce the risk of errors during production. Click https://www.by3design.com/ to learn more.

The rapid prototyping process allows companies to create a physical prototype of a product concept with little cost or time investment. The iterative nature of the process allows designers to gather feedback and make changes based on user input. This saves time and resources that would be spent reworking or redoing a final design that won’t work in production, and helps to ensure the company is developing products that are relevant for their target audience.

The process begins with a computer-aided design (CAD) model that is then converted into a format compatible with the chosen prototyping method. This can be done by a software program or manually. The machine is then set up with the appropriate material, such as plastics, resins, metal powders, or ceramics. The machine then builds the prototype layer by layer, adhering to the specifications of the CAD model. The prototype may then require additional post-processing to achieve the desired appearance or mechanical properties.

Once the initial prototype is completed, a series of tests are conducted with users to evaluate its function and usability. The feedback from these tests can be used to make changes to improve the design and functionality of the prototype, which in turn can help to ensure that it will perform as expected in the real world.

The iterative nature of this process also encourages greater creativity and innovation. By allowing teams to experiment with new designs without having to invest the time and money required in traditional prototyping methods, this allows them to explore different possibilities and find more innovative solutions to existing problems. This can be particularly beneficial in industries like consumer products, where consumer preferences and expectations are constantly evolving.

While the benefits of rapid prototyping are clear, there are certain things that must be avoided in order to get the most out of the process. These include:

Overlooking Design for Manufacturing: Failure to account for the nuances of manufacturing can lead to costly redesigns down the road. To avoid this, it is important to ensure that the prototype is built using materials that closely match the desired final properties of the product.

Additive Manufacturing

Additive manufacturing (AM) is a process that builds up layers of material to shape an object. It’s an alternative to traditional “subtractive” manufacturing techniques that work by cutting away sections of material. Unlike conventional techniques, AM can produce complex shapes and intricate details that wouldn’t be possible using other processes.

AM can also produce components on demand, reducing inventory costs and lead times. By eliminating the need to store components, companies can keep inventories lean and increase productivity by producing parts as needed. In the electronics industry, AM can be used for lean manufacturing by enabling the quick production of replacement parts when required, eliminating costly downtime and repairs caused by stock-outs or faulty equipment.

Compared to conventional injection molding and composites layup, 3D printing is more cost-effective for low volumes of parts because it doesn’t require molds or tooling. This is particularly true when the geometry of a part is complex and requires a high level of precision.

The use of additive manufacturing can improve the quality of finished products by minimizing defects and improving surface finish. For example, AM technology can print parts with smooth surfaces without a support structure which would otherwise leave blemishes. In addition, post-processing technologies such as sanding and painting can further enhance surface finish.

Another benefit of AM is that it can help reduce the environmental footprint of a product by limiting waste generated during the manufacturing process. For example, the energy industry uses AM to fabricate lightweight electrical components that can withstand power spikes and surges. This helps reduce the need to transport and store heavier, more energy-intensive components that aren’t as efficient or environmentally-friendly.

Consumers today expect customized products that are made to their exact specifications. Additive manufacturing is allowing companies to meet this demand by reducing the time and expense of creating new tools based on consumer feedback. In addition, mass customization can be used to create unique or limited-edition products. Footwear company Superfeet, for instance, can now design and produce a custom pair of shoes in less than an hour using AM.

Customization

3D printing makes it easy to customize a product or part according to the needs of an individual. This is a powerful marketing tool that allows companies to tailor their offerings to the needs of a particular audience, increasing sales and retention rates. It also enables companies to offer products in small batches or on demand, eliminating the need for large warehouses and inventories.

The ability to create parts with unique geometries makes 3D printing a highly flexible manufacturing technology. For example, a metal 3D printer can fabricate parts with complex curves or shapes that cannot be easily or economically produced using traditional subtractive manufacturing processes. It can also make parts with custom cooling channels to enhance performance or provide additional functionality.

This flexibility has also led to a number of other benefits. For example, our customers in the consumer electronics industry use 3D printing to create prototypes of a component or a product’s design before it moves into production. This helps them test a new or updated design against existing components to ensure that it will perform as intended. It also gives them a chance to see how the part or product will fit together and assemble correctly, identifying any potential issues with functionality or design before full-scale production.

Moreover, 3D printing can be used to produce spare parts quickly and on demand. This can help reduce inventory costs and increase the availability of parts for customers, which is important in a fast-paced market. It can also be used to produce durable housings for sensitive electronic parts that are resistant to a range of elements, including heat and water.

In addition to being a versatile manufacturing technology, 3D printing is also an ideal home hobby for individuals who are interested in creating a variety of products and creations. From creating sculptures to designing a home, this type of printing can bring out a homeowner’s creativity and allow them to build something completely unique. However, homeowners should be aware of the noise created by these machines and take steps to protect their hearing.

Sustainability

Sustainability is an ever-increasing priority for both customers and businesses. Many manufacturing processes generate noxious gases and waste that are harmful to the environment and contribute to climate change. Additionally, the energy used to transport raw materials and finished goods across long distances often produces significant carbon emissions. 3D printing offers a more environmentally conscious alternative to traditional manufacturing methods by eliminating these harmful and wasteful steps.

Conventional manufacturing techniques require large amounts of water for cooling and cleaning processes, resulting in considerable environmental waste. Additionally, they often produce substantial quantities of unused product and discarded materials. 3D printing, on the other hand, requires only minimal energy to heat the printer and print the desired products. Furthermore, additive printing only uses the amount of material required for the final product. However, it does create some waste in the form of support structures that need to be removed from the printed object (SLS and SLA).

The most popular 3D printer technology is fused deposition modeling or FDM which only requires a small quantity of material for each printed object. Moreover, the plastic filaments used in this process are made of recycled materials which are more environmentally friendly than virgin plastic. This is because recycling reduces the need for raw materials and energy for their extraction, processing and production.

Another aspect of 3D printing that supports sustainability is its ability to be used with a wide variety of materials, including metals and a number of different types of plastics. The ability to integrate these different materials opens the door for a number of new sustainable possibilities. For example, one furniture company uses a PLA matrix filled with different waste materials that can be consumed by bacteria in industrial composting facilities, thereby producing an eco-friendly and biodegradable material.

Other initiatives are also taking place to promote sustainability in the manufacturing industry, including the use of repurposed and recycled materials for 3D printing. Some companies are even experimenting with building with the help of Markforged printers. Construction company Mighty Buildings, for instance, has begun using a concrete formula that significantly reduces CO2 emissions by 50% compared to conventional cement.